Pipeline ROV inspection in Mexico

| Service | ROV Pipeline inspection and Cathodic protection survey |

| Location | Gulf of Mexico, offshore Ciudad Del Carmen, Campeche. |

| Water depth | 15 – 130 m |

| Project duration | 10 months (2018) |

| Industry | Oil & Gas |

The scope of the work included:

- ROV general visual inspection (GVI) of the pipelines with the aim to identify their locations and physical conditions.

- Cathodic protection survey by measuring the CP potential and verifying whether or not the anodes are still functional.

- Evaluate the conditions of the concrete mattress, their position on the ground, interconnections and crossings with other existing lines to identify any potential hazard that might affect the stability and structural conditions.

- Identify any natural and artificial hazard on the seabed, as well as objects that have fallen to the bottom of the sea and/or are abandoned.

- Detection of gas or oil emanations (leaks or dirt tracks), line displacements with respect to its laying alignment, undercuts, anchor dragging and location of objects fallen to the seabed (metal debris in direct contact with the line).

- Calculate the burial depths of submarine lines and interconnections.

- Detect freespans and scours.

- Detect consumed and inactive disconnected anodes.

VESSEL

The vessel was able to accommodate 66 people, including Crew, ROV personnel, survey team and Client’s reps.

ROV

However, the potent thruster power of the Panther was able to handle a large array of equipment needed for full survey work and provided the steadiness and agility needed to continue working even in strong currents.

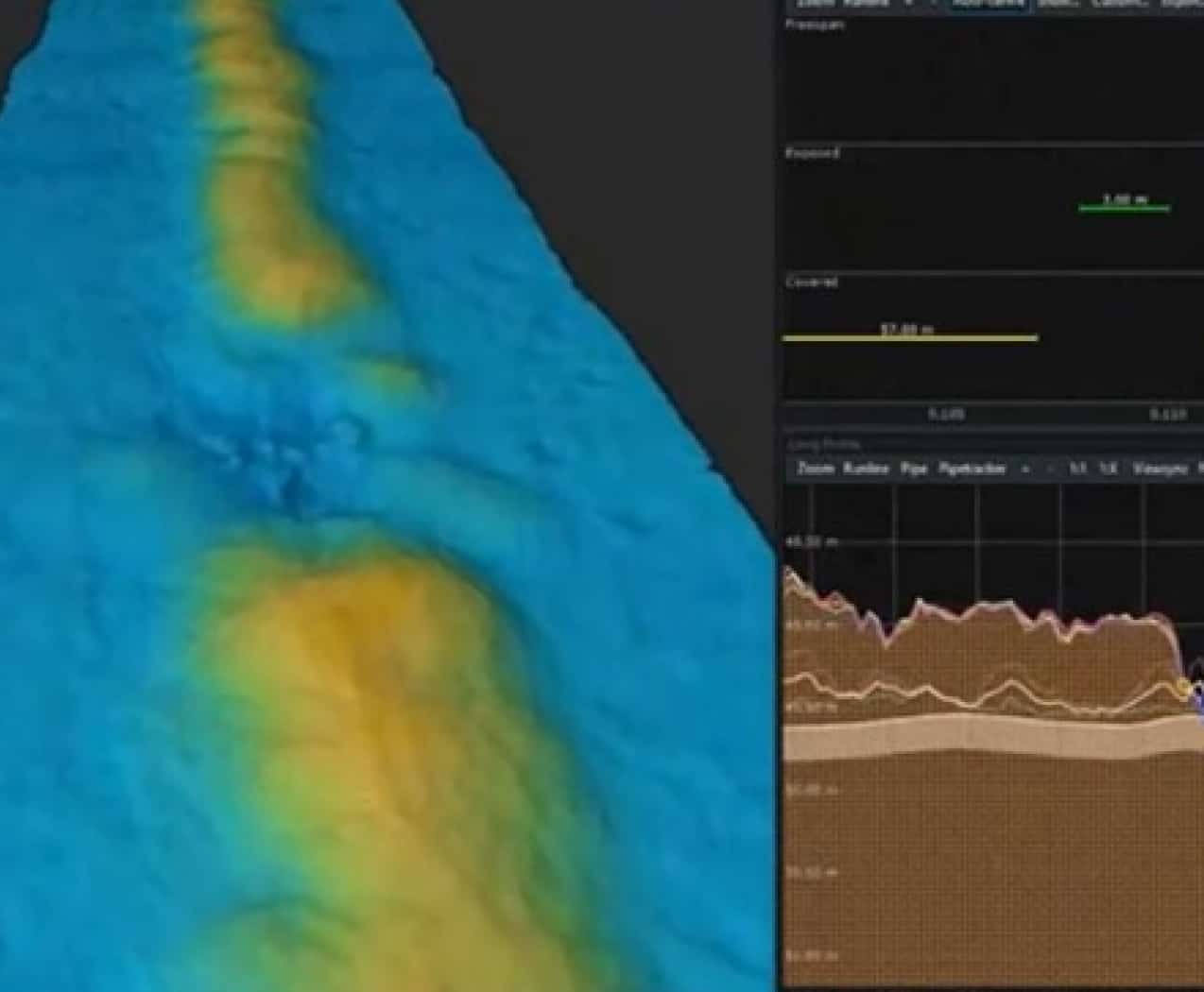

In addition, the electric vehicle was acoustically quieter than hydraulic vehicles that means the Panther was able to provide accurate multi-beam sonar data.

SURVEY EQUIPMENT

Where the pipelines were exposed, dual MBES data acquisition and visual inspection have been carried out to identify any possible faults/hazards. The cathodic protection system measured the CP potential over the pipeline with the aim to estimate the life time of the anodes.

The recorded data have been acquired and processed by using EIVA Navimodel that allowed to work simultaneously with different kind of data (MBES, pipetracker, pipe model, CP values, videos and blue-view from ROV) and deliver user-friendly formats to the Client.

ACSM inspected 261 pipelines totaling of 2,340 km in four fields in the Gulf of Mexico (GOM), at depths ranging from 15 to 130 meters, in a less than 10-month project duration.